After introducing the first closed loop recycled tray in the industry with KLM, deSter is further engaging in major initiatives to implement circular processes for airline tableware plastics. Catering equipment, once they reach their end of life, would be collected and reprocessed in a complex supply chain, until they are remanufactured into the same products, hence preserving the value of material.

One obstacle presented itself: in the fast moving and usually tight environment of an airline catering unit, how to handle and prepare waste to be transported to a recycling facility?

Despite seeming simple, this problem can be a major hurdle preventing airlines and catering companies from engaging in waste segregation. In addition, if a recycling process is implemented without minimizing the impact of waste handling, it risks being inefficient and delivering a low material value.

In the second phase of the project they took PET cups and bottles as a pilot group. These products are the most easily segregated on board or in the catering facility. The team designed a material handling system that had 2 objectives: drain the liquids out of beverage bottles and compact the size of the waste.

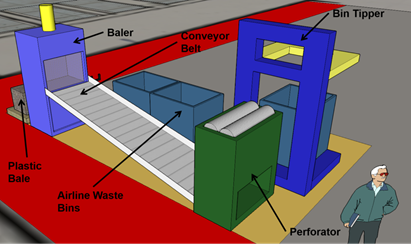

The low-budget proposed solution included a perforator and a mini-compactor, both equipped with a conveyor belt and a bin tipper to facilitate operator handling.

For the new process to blend into the busy workload of operators, it was important to define how often an operator shall run the compaction process. This question was translated into a sophisticated mathematical formulation, which, if tracked simply on a spreadsheet, can allow the facility supervisor to plan resources.

This project unveiled several positive outcomes: handling and recycling airline waste in a busy catering facility is feasible and can be inexpensive, students are highly skilled with techniques and enthusiasm to solve complex questions, and collaboration between the industry and academia is rewarding to all parties.

However, the key to bring such effort to fruition is implementation, and deSter, gategroup is committed to work with airlines to close the loop on cabin plastic waste.

deSter is part of the advisory committee for the newly launched Global Tourism Plastics Initiative, led by the UN Environmental Programme and the World Tourism Organisation in collaboration with the Ellen MacArthur Foundation.

*Lebanese American University, School of Engineering, Department of Industrial and Mechanical Engineering https://soe.lau.edu.lb/ime/

Link to the school’s article on the project: https://news.lau.edu.lb/2020/students-crack-the-code-for-airline-waste-problems.php