deSter stands at the forefront of the food packaging and serviceware industry, delivering innovative and sustainable concepts to the aviation and foodservice sectors. With a remarkable manufacturing history spanning more than 50 years, our journey began with a legendary fries fork. Today, our product range covers the entire spectrum of in-flight equipment and food packages, including innovative solutions for premium segments.

Over the years, we have expanded globally, and today, we operate manufacturing facilities in Belgium, the USA, Thailand, as well as Barcelona (part of deSter x Nupik), embodying a glocal approach. Our strategic presence across three continents enables us to reduce delivery times, minimize costs, and lower CO2 emissions by producing closer to our valued customers. Previously, we highlighted our US facility in Lima, Ohio, and our Prachinburi factory in Thailand. Today, we invite you to take a closer look at our headquarters — Hoogstraten, Belgium.

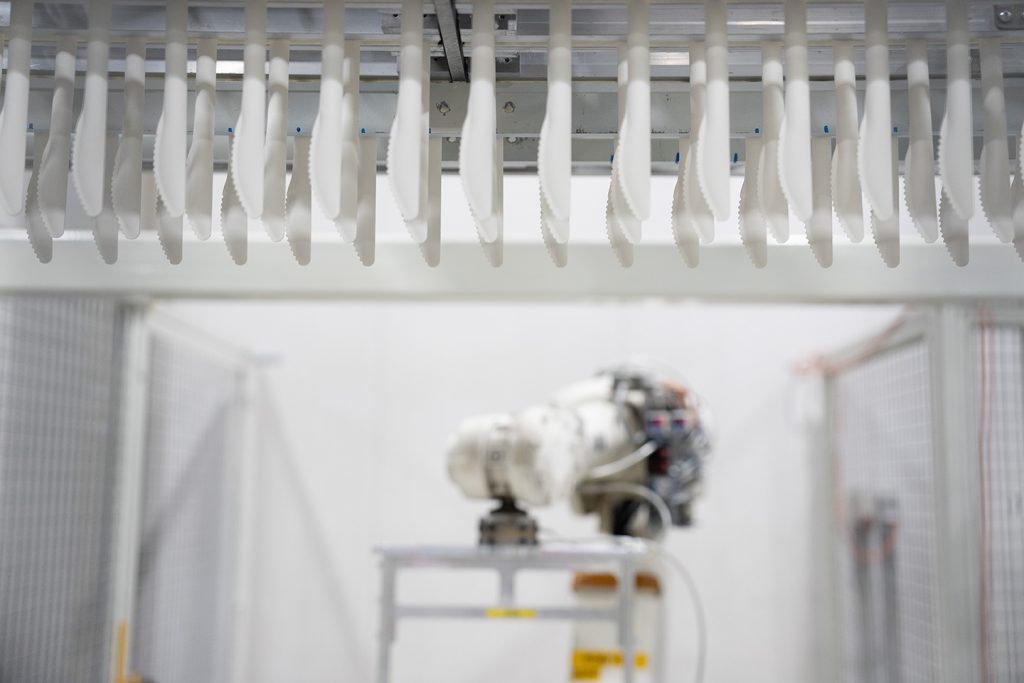

Spanning an impressive 170,000m², the Hoogstraten facility houses both our corporate office and our largest production site, setting the benchmark for innovation and operational excellence. With a diverse range of manufacturing techniques, including injection molding (24%), extrusion and thermoforming (54%), and catering solutions (22%), this site produces an extensive portfolio of products that serve the aviation and foodservice industries worldwide. Our production capabilities include reusable and single-use tableware such as meal trays, cups, bowls, casseroles and cutlery. We also specialize in condiment filling as well as hygienic products like disinfecting wipes and gels. A standout innovation is our patented paper cutlery technology—an advanced alternative to traditional single-use plastic, offering a compostable, sustainable solution with a superior mouthfeel compared to wooden cutlery. In addition, in our Hoogstraten facility, we produce reusable cups and integrate RFID chips (supplied by our partner) for one of our customers, Royal Antwerp Football Club (RAFC).

As the largest of deSter’s production sites, Hoogstraten is also a leader in sustainability. We have implemented energy-efficient practices, including LED lighting and an advanced water recycling system that minimizes waste during production. Our commitment to responsible manufacturing was recognized in January with the ISO 14001 certification, reflecting our dedication to environmental stewardship. Additionally, we prioritize waste sorting and continuously seek new ways to reduce our environmental footprint across operations.

Beyond manufacturing, we believe in fostering strong connections within our local community. We actively collaborate with local schools, providing internship opportunities for students interested in manufacturing and engineering, helping shape the next generation of talent. Every December, our team unites for a company-wide fundraising event, supporting charitable initiatives that make a tangible impact.

With a rich history, cutting-edge innovation, and a steadfast commitment to sustainability, deSter’s Hoogstraten facility serves as a model for our global operations. It’s more than just a manufacturing site—it’s where ideas take shape, where sustainable solutions become reality, and where we continue to push the boundaries of what’s possible in foodservice and travel catering solutions.